Traditional 4WD systems are still available, but as time goes on, their prevalence has lessened greatly. They work manually, and are very effective overall.

Locking front and rear drivetrains together makes the vehicle jerk and lurch in good traction, especially while turning. (This is called driveline windup or tight comer braking.) These systems will wear out quickly or break if used extensively on clean pavement.

While unlocking manual free-running front hubs saves fuel and cuts wear on the front driveline, the driver must know the hubs’ position without an indicator. When locked, they allow `shift-on-the-fly’ 4WD engagement. However, shifting into 4WD while driving with the hubs unlocked could lead to `powertrain parts on the fly!’

While unlocking manual free-running front hubs saves fuel and cuts wear on the front driveline, the driver must know the hubs’ position without an indicator. When locked, they allow `shift-on-the-fly’ 4WD engagement. However, shifting into 4WD while driving with the hubs unlocked could lead to `powertrain parts on the fly!’

Many off-road drivers prefer this system. Simple and reliable, when combined with limited-slip differential options it can be nearly unstoppable in extreme conditions. But most motorists don’t encounter such extremes and prefer something more user-friendly.

Full-time four-wheel-drive

Often also called all-wheel-drive (AWD), basic AWD uses an open differential at the transfer case to relieve powertrain loads (driveline windup) developed as front and rear wheels travel varying distances around curves. However, the open differentials may allow the one wheel lacking traction to get all the torque in extreme situations. The chief purposes of AWD are to improve everyday driving feel on dry pavement, increase power delivery to the ground and enhance traction in `routine’ slippery driving, such as rain-slicked or snowy highways. This isn’t king of the hill for off-road trailblazing.

Infinite (confusing) variety

Few new vehicles offer full-time or part-time 4WD in pure form. Part-time variants include automatic locking hubs, electric or vacuum connection/disconnection of front halfshafts, electrically-shifted transfer cases, and electromagnetic front driveline spool-up clutches.

Full-time systems have been enhanced with viscous couplings or hydraulic clutch packs to progressively lock front and rear drivetrains or with manually-lockable center differentials for rough going (in effect, adding part-time 4WD to full-time 4WD).

Getting the front driveline up to speed

Standard, part-time 4WD may be shifted `on the fly’ as long as the front driveshaft yoke is moving at-or nearly at-the same speed as the shaft or gear it engages in the transfer case. Otherwise, there will be a severe shock to the powertrain upon engagement.

If all four wheels are moving at or very near the same speed and the front hubs are already locked, all is well, since the front drivetrain and transfer case are in more-or-less synchronized motion. But having the front halfshafts locked to the hubs isn’t the only way to get the driveline going.

One method borrows from air conditioning practice. When 4WD is selected, an electromagnetic clutch starts the driveline turning, spooling it up to speed very rapidly–though not suddenly enough to do harm. Meanwhile, engaging the transfer case–once handled by wrestling a `Johnson bar’ on the vehicle floor–is handled by an electric motor. Typically, the motor spring-loads a splined collar, which slips into place and locks input and output shafts together when rotational speeds match.

So far, so good, but today’s more `user-friendly’ systems don’t require the driver to stop and lock the front hubs before shifting into 4WD on the fly. But on the other hand, even if the front prop shaft is disconnected at the transfer case, all the front driveline parts still turn–wearing and using fuel–if attached to the wheels. That’s why free-running hubs were developed. In fact, one advantage of part-time 4WD is that much of the front driveline isn’t in motion when in 2WD.

Even most of the simplest-to-use, push-button 4WD systems allow the front driveshaft and ring-and-pinion to rest when in 2WD. In some, the shorter front halfshaft is always connected to the hub on its side, so the short shaft, the differential spider gears and the CV joints turn whenever the truck is rolling. In 2WD, however, the longer halfshaft is disconnected from its spider gear. When 4WD is selected, an electromagnetic or cone clutch brings the front driveshaft up to speed while an electric motor and spring (or a vacuum servo) at the front axle pushes against a splined, locking collar on the halfshaft. When speeds match, the collar snaps into place.

The other system employs automatic locking hubs. Just as manual locking hubs engage when you turn the knob to spring-load a locking collar within the hub, the turning motion of the axle coming up to speed engages a cam inside the automatic hub. This loads a similar spring, causing the collar to slip into place and engage the hub-once hub and shaft speeds match.

Progressive lockup for full-time systems

Although severe off-road conditions were not the top priority when engineers initially designed most AWD systems, they’ve developed effective ways of dealing with full-time 4WD’s chief weakness under poor traction, the unlocked center differential.

One strategy, already mentioned, is to have the ABS computer use wheel-speed sensor information to selectively grip brakes at spinning wheels. Two other approaches-the viscous coupling and the hydraulic clutch pack-add progressive lockup capability at the transfer case.

Viscous couplings provide locking action while tolerating enough slippage to allow cornering with very little driveline windup. The coupling interrupts the driveline to one end of the vehicle. It contains a series of clutch discs bathed in a silicone-based fluid. Half (every other) of the discs are connected to the coupling’s input; the other half are splined to its output. If both sets of discs are moving at or near the same speed, nothing remarkable happens. But when a wheel starts to spin (or, in some cases, the vehicle takes a very sharp comer), the relative motion of the discs quickly heats the fluid, which thickens, sticking the discs to each other, nearly locking the coupling’s input and output. When conditions change, the fluid cools quickly, relaxing its grip.

Hydraulic clutch packs resemble viscous couplings, with clutch discs splined alternatively to the input and output sides. However, instead of using friction, heat and temperature-sensitive goo, pressurized hydraulic fluid pushes the discs together. Pressure varies based on signals from a microprocessor acting upon readings from wheel speed sensors.

Which is it?

It’s important to know which system a vehicle uses to troubleshoot it correctly, but how do you tell which it has? Sometimes it’s obvious: a floor-mounted lever and locking hubs mean `traditional’ 4WD. If there are no switches or levers but there are front and rear drivelines, it has AWD. (Note: Some AWD systems do have controls for options like locking center differentials.) However, there are variations on both AWD and part-time shift-on-the-fly systems. The next step is consulting the owner’s manual and comparing components with systems described in the manual. Manufacturers we consulted say the VIN is not reliable for identifying drive systems, but matching the manual’s description of controls and characteristics to what you see is helpful.

Depending on the system in use, a customer complaint may mean a complicated problem or something simple. For example, a sport-ute may lurch around comers on dry pavement for several possible masons:

Nothing is wrong, but the part-time transfer case hasn’t been shifted out of four-wheel-drive;

The driver has attempted to disengage 4WD but the system won’t shift out;

A progressive-lockup clutch in AWD is locking inappropriately. Hydraulic or control system failure could be the cause.

Tire troubles

Something as simple as mismatched tires can cause problems in tough, reliable 4X4 systems. Not only size matters: All four tires should be the same make and tread design. Variations in inflation pressure can cause a change in effective circumference–making the tires behave as though they’re different sizes, loading up the driveline and causing windup even while traveling in a straight line. Rotating tires helps prevent uneven wear which can cause noise and erratic driving characteristics. The practice may also prevent actual changes in tire diameter.

Tire mismatches (or turning on dry pavement) can cause 4WD to remain engaged when the driver tries to shift it out. This may happen when the front-drive locking collar is under stress and can’t be pushed away by the spring meant to disengage it. The resulting, continuous lurching could cause damage. Driving straight forward and back on a reduced-traction surface may let the collar release. If not, jack up a front wheel. If it spins as it leaves the ground followed by the `thunk’ of a collar slipping out of engagement, you’ve just released a wound-up driveline. Check the tires and/or instruct the driver against running in 4WD on the road. If the system is electrically shifted and doesn’t release when jacked up, check for current at the engage/disengage motor.

Different uses, different maintenance

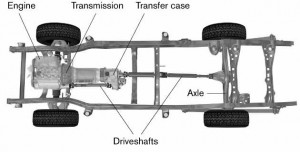

Talk with your customers about their 4WD/AWD vehicles and how they use them. Most won’t subject their vehicles to off-road driving or hard work. Be sure they’re aware they have extra components (a transfer case and an extra driveline with another differential and possibly extra Cardan or CV joints) which need servicing. And be doubly cautious about fluids when doing routine preventive maintenance. For example, many All-Trac Toyotas with automatic transmissions use ATF in a hydraulic clutch pack. There’s potential for confusion because the pack is located inside the transfer case where the remaining parts are lubed with gear oil!

Customers who bought part-time 4WD just for use on snowy roads need to know the `ten-mile-a-month’ rule: If the front driveline sits idle for too long, gears may rust and seals may stick to shafts. They need to find some low-traction surfaces and exercise their systems.

Any part-time 4WD driver needs to know that engaging the system after it’s already needed is bad news. For example, if the rear wheels are spinning, kicking in the front driveline (which is just turning at the truck’s forward speed) can cause violent engagement, and expensive damage. They should engage 4WD when conditions are slippery, but before wheels start slipping.

Off-road customers (and your own truck) may see tough duty. Manufacturers may specify synthetic gear lube for towing, plowing or desert rock climbing, while allowing mineral oil for less severe driving. The judgment call should be made based on your experience and knowledge of the customer’s habits.

Off-road trucks may be subjected to dust, which can clog filters. On the other hand, crossing rivers means that under-vehicle fluids will need changing to remove water, and unsealed U-joints will need greasing. (Be careful if pressure-washing to remove mud. Excessive pressure can blast water and detergent right past axle seals and even damage hoses and wires). Rough, off-road brush can tug at wires and hoses under the vehicle, requiring frequent inspection. Because there are all kinds of 4WD and all kinds of drivers, you need to be ready to do all kinds of 4WD maintenance!

Leave a Reply